Clay. It's the material that bricks are made of. We reckon that's pretty common knowledge (although if you didn't know, there you go!).

If you're in the market for bricks and want to make an informed decision, you may have wondered whether the clay used has any significant impact on the quality of the bricks themselves.

Can you even select bricks based on clay? And is it something you should put much thought into?

The short answer is no. The type of clay used won't have any significant impact on the quality, durability or load bearing capacity of the brick.

Of course, it can have an impact on what the brick looks like, so this may be something you want to know more about.

For those who want some extra info on clay and its use in making bricks, read on.

Request a quoteWhat's the difference?

There are of course many different types of clay found on planet earth.

Clay is a type of fine-grained soil that is formed from a mixture of weathering and erosion to large rock formations over millions of years.

It's usually found in layers with different levels of minerals and elements in each. This can give each layer a different colour.

It's this colour that ultimately has the biggest effect on the end product.

Different kinds of clay can produce different colours of brick, whether that's an orange or red, a lighter yellow or an even lighter white or grey.

Different clay minerals can also react differently during firing, their composition changing how long they need to be fired for and what the atmosphere of the kiln should be like.

Colour isn't always affected by the clay however as this can also change during the firing process. For example, most blue bricks, such as the Staffordshire Blue, gain their colour from the high temperature they are fired at.

All these decisions are ultimately down to the manufacturer.

Different kinds of clay can produce different colours of brick and react differently during firing

Maker's mark

Manufacturers of good quality bricks, whether they are larger companies or smaller independents that specialise in handmade bricks, will make sure the clay they're using is high grade.

Before mining clay in the first place, the ground is tested for all the components of the soil found there.

One of the reasons brick is such a popular building material is that the clay used to make it is so abundant.

There are clay deposits all over the earth's surface and each one has its own unique properties producing the different colours we see in bricks.

Geology rocks!

Here's the science bit... Clay is different to other forms of soil in that it has a higher plasticity. This means when wet and fresh out of the ground it is quite mouldable.

This happens because the aluminium and silicon bonds in the minerals are connected by a film of water molecules. This allows these bonds to move around.

When bricks are fired, this water evaporates meaning the bonds fuse together directly, causing the rigidity that we know and love.

Within the most common kinds of clay, such as kaolinites and smectites, are often found small quantities of quartz, metal oxides and organic matter from millennia of formation. This all adds to the interesting composition of the clay.

Informed choice

Ok, science lesson over. The good news is, when you're picking your bricks, you don't really need to worry about the type of clay used when you assess brick quality.

Unless of course you are interested in where the clay has come from. This might be because you want your new build or self-build project to have its roots firmly in a particular area of the country.

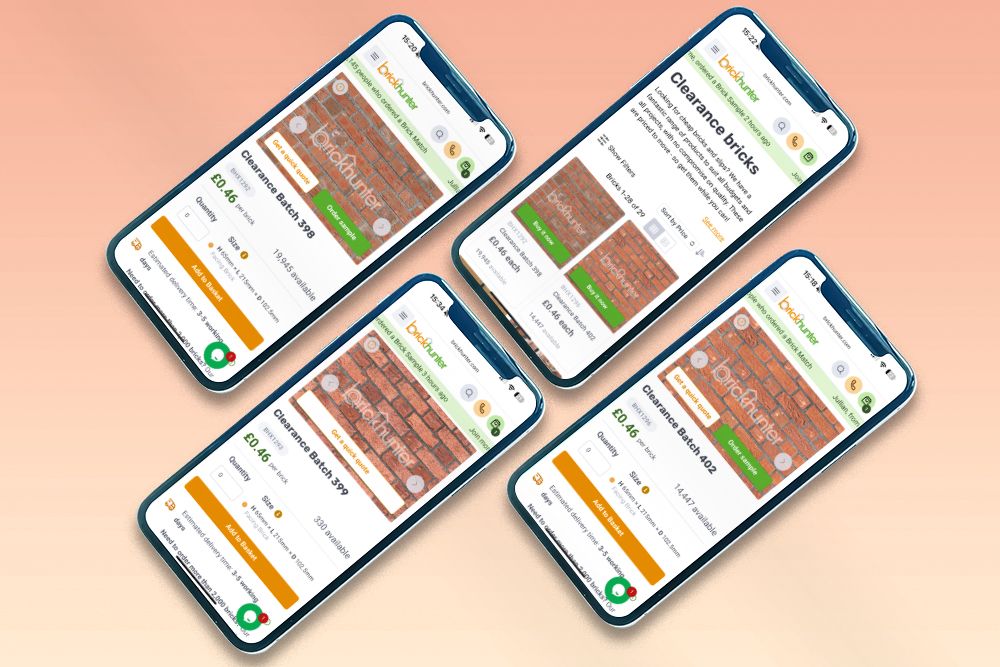

As a brick matching and brick selection provider, we can help you find the brick you're looking for.

We'll do the digging (not of the clay -- we'll leave that to the miners!) and get you some bricks with your origin of choice.

Why Brick Tests Matter

Even though the type of clay doesn’t usually dictate quality, it’s only one part of a larger picture about strength and durability in good quality bricks. That’s why brick manufacturers and suppliers conduct a range of key tests before you choose a brick:

⦿ Compressive strength test and load bearing capacity are essential. A brick’s high compressive strength rating ensures it can safely support the weight of upper floors or structural loads. In the UK, many facing bricks are required to exceed at least ~3.5 N/mm² (≈ 35 kg/cm²), with top‑tier engineering bricks delivering upwards of 75–125 N/mm² (between 75 and 125 MPa). Such results are usually measured via compressive strength test protocols in a lab.

⦿ Water absorption test is another critical assessment. During a water absorption test, dry bricks are weighed, submerged in water for 24 hours, and weighed again — the percentage increase shows how much water they absorb under extreme conditions. Clay bricks with low absorption (say under 12% for Class A or Class B) retain structural integrity better and bond more reliably with mortar.

⦿ Testing for soluble salts or efflorescence is also standard - bricks are soaked and inspected after drying for white or grey residues. Excess salts can weaken the brick surface, undermine mortar adhesion, and compromise aesthetics and longevity.

⦿ A water weight test (a simple field version of absorption testing) lets you check on-site whether the brick gains excessive weight in water - an indicator of porosity, potential frost vulnerability, and long‑term durability.

⦿ Some unique practical tests, like dropping a brick from a height or striking two together, allow builders to gauge soundness: a clear ringing indicates good internal bonding and strength and durability in the field.

With these assessments, you can make an informed decision on whether the brick offers the “stand the test of time” performance you expect.

During a water absorption test, dry bricks are weighed, submerged in water for 24 hours, and weighed again — the percentage increase shows how much water they absorb under extreme conditions

Why These Tests Matter More Than Clay Type

By layering the clay’s geological origin with rigorous quality tests, specifiers and builders gain confidence in the brick’s load bearing capacity, structural integrity, and long-term quality brickwork outcomes.

Even if clay variety has little effect on performance, the post‑firing density and absence of defects will determine whether the brick achieves both high compressive strength and low water absorption.

Combined with controlled firing, these outcomes define whether a brick will stand the test of time in real conditions.

Bridging Science and Practical Choice

If you’re comparing bricks—say for matching heritage London stock or choosing engineering brick for damp-proof courses—you’re likely choosing based on test certificates like:

⦿ Compressive load metrics (e.g. > 75 N/mm²)

⦿ Water absorption figures (e.g. < 4.5% for Class A engineering bricks, under ~12% for high‑quality facing bricks)

⦿ Statements about soluble salts or efflorescence resistance

⦿ Lab evidence or visual inspection indicating no cracks, stones or imperfections

This range of testing gives you the power to choose good quality bricks, regardless of clay origin.

It also allows you to compare options confidently, making an informed decision - because ultimately, what matters is not the colour or source of the clay, but how that brick performs in key tests that predict real-world strength and durability and whether the quality brickwork you deliver will stand the test of time.

Make Tests Your Guide

While clay type shapes a brick's appearance, it’s compressive strength test, water absorption test, salt testing, and simple practical checks like a brick from a height drop or water weight test that determine suitability.

Focus on load bearing capacity, structural integrity, and durability metrics - and you’ll be well placed to choose good quality bricks to underpin durable, long‑lived quality brickwork.

With those figures in hand, you can make an informed decision - ensuring your bricks have the high compressive strength and low absorption needed to perform, and that they truly stand the test of time.

We're here for you

If you hadn't realised, we love bricks. And we love finding out where they come from.

If you're thinking about starting a building project, we have a range of services tailored to help you achieve successful brickwork - whatever the shape of your build or the size of your ambition.

Our expert Brick Advisors are standing by to help you match, customise and calculate the exact amount of bricks you need, then source them and find the best price - we'll even arrange delivery too.

Simply let us know what you need, and our experts will do the rest!