Generally, bricks don't need to be cut. They are sold in the size that you want and are ready to be used for building walls. But there are some instances where modifications are needed.

There are different reasons why you might cut brick and a number of different ways to do it too. But if you need to cut some bricks for your project, you may be unsure how to proceed.

The easiest and safest way to get brick cut to your specifications, particularly if the task is complicated, is to employ a specialist.

And we work with the best in the business to make sure you get everything you need when you need it.

Contact the teamWhen to do it

While there isn't an automatic requirement to use specially cut bricks on every build, certain projects call for certain bespoke elements - and sometimes you just need a bit of extra help:

Lack of availability

Not all bricks are made forever and different textures, blends and shapes will get discontinued if they fall in popularity. This means that if you want to match a pre-existing structure or have a particular visual style in mind, you're reliant on bricks already on the market.

One option is to browse the reclaimed market. But you could also use brick cutting to get a specific shape or size. Much older bricks have different sizes or thicknesses, so your new bricks may need to be cut to fit in with the rest of an older building.

To meet specific needs

A growing market in world of building and architecture world is that of brick slips. There is a wide variety of styles available, and we would generally advise buying specially made brick tiles. They're easily accessible and you can get them installed too.

That said, no matter where they've been manufactured, brick slips will almost always originate from an original clay brick product. It may be that you have a particular style, colour or texture in mind and want to replicate that in brick tile form.

Fortunately, with brick cutting, it is possible to create a brick slip from existing bricks.

For the bespoke touch

Many buildings need some special-shaped bricks (specials), so this is one of the most popular uses for brick cutting. If you're buying normal bricks, it makes sense to get your specials at the same time.

Of course, lots of brick specials are factory made but buying these can work out more expensive and there's often a lack of variety when it comes to colour choice.

Alternatively, the one you want may be hard to get hold of. If you want something bespoke to your structure, it may be difficult to find the special brick to match.

Fortunately, more straightforward specials such as plinth bricks can be made by cutting the bricks you've already ordered.

Don't-It-Yourself!

In some instances, you may be tempted to cut your bricks yourself - and, for simpler cuts, that's how it always used to be done.

But did you know, that in most regions of the country, regulations stop even bricklayers cutting bricks onsite. If it's considered too dangerous for people on a building site to do, then it's not something you should be trying at home.

The main reason you shouldn't be taking a saw to a brick is because of the size of the brick. There's almost no guarantee you will have sufficient control over something of that size whilst you attempt to use a power saw.

The dust coming off the brick whilst it's cut can also be unhealthy. Now considered to be carcinogenic, even with a mask, you don't want to be creating a load of dust in an area where other people are working.

If it's considered too dangerous for people on a building site to do, then it's not something you should be trying at home

Leave it to a pro

The best course of action here is to seek out the help of a professional cutter - and this isn't just because they've got more experience, although that certainly helps.

Brick cutters, whether working with brick merchants or building developers, will use specialist equipment at their own premises to do the job. This is not only more accurate but it's a lot faster too.

These machines can cut bricks five times faster than doing it with other tools. The cost saving of doing it this way ultimately trickles down to the developer and subsequently the homeowner.

How it's done

When a customer has requested cut bricks and provided the angles required, the work gets done offsite and the finished specials or fabricated bricks are delivered to the site on completion.

Brick cutting machines are water fed, meaning any of that harmful dust is immediately suppressed and taken off the brick and out of the immediate atmosphere of the workers. This also means the cut bricks are completely clean.

If fabricating specials, sometimes cutting specialists will bond two pieces together to create it. Trustworthy specialists will use BBA approved epoxy adhesive meaning those joints won't open or crack down the line.

The adhesive will also be coloured with brick dust so that the joint is seamless and to the human eye it looks like a completely clean cut.

We're here for you

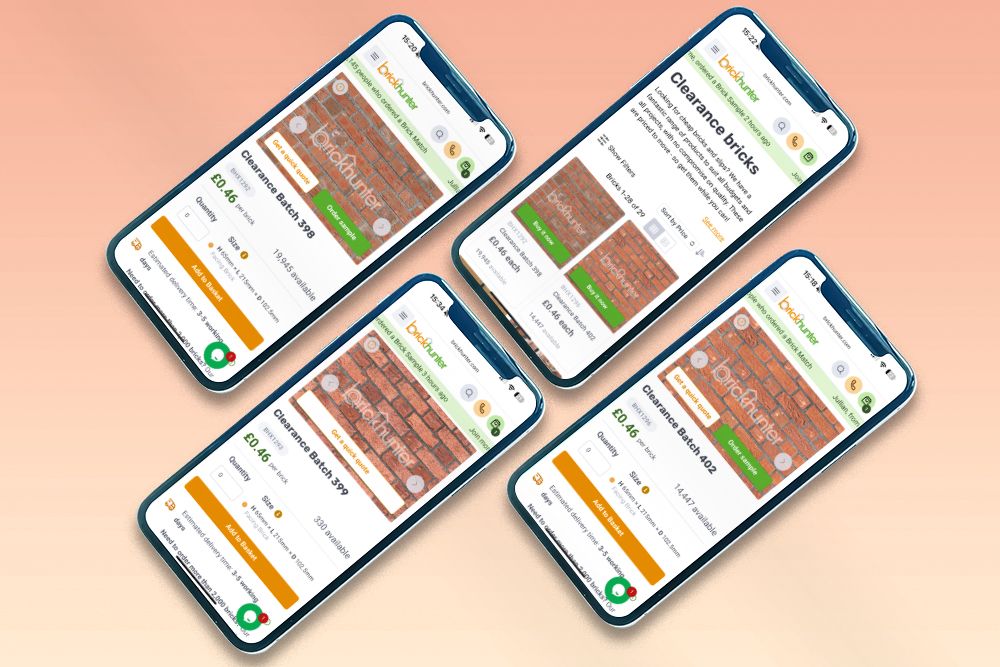

We love making it easy for you to build with bricks, which is why we've added a specialist brick cutter to our list of trusted partners.

They use the techniques mentioned above, including strong adhesive, where needed and significant time saving for your project or development.

If this is a service you need, let us know - we can get your bricks cut any way you want.