Today's technology-focused society has witnessed numerous advances, including the internet, AI and virtual reality. It seems every industry can benefit from these advances, but the construction sector is making some impressive strides.

3D printing is revolutionising the industry as a whole, and brick construction is just one area where we're seeing impressive results.

In this guide, we'll explore what 3D printing is and how it's changing brick construction - and if you need help sourcing some bricks, our team is standing by to find the bricks you need at the best prices.

Request a quoteWhat is 3D printing?

Before 3D printing, manufacturing materials was an intricate - and highly specialised - process, but technology revolutionised how people think about producing materials.

Also known as additive manufacturing, 3D printing lets you turn a digital file into three-dimensional objects through a streamlined process.

In terms of construction, 3D printing enables specialists to create digital models, saving resources and time. Let's take a look at the different ways this technology is changing construction.

Planning and design

No construction project would be successful if it weren't for a seamless planning and design phase.

Engineers and architects can now conceptualise their designs and see if they're viable without wasting materials, ensuring more accuracy and efficiency.

Not only does this mean architects can streamline projects, but it also allows for more innovation, which was previously too expensive.

Efficient projects

Another major benefit of 3D printing in construction is the speed it allows. Projects that took months or even years now take days to weeks because the printers can assist with all planning elements.

Technology can promote positive changes and ensure ongoing progress when we think about natural disasters or rapidly developing countries.

Affordability

OK, 3D printing technology is an investment, but the money you spend initially results in prolonged savings for your construction projects.

Why? Because 3D printers can help you evaluate the resources you'll need for a project and how many people you'll need to complete it.

Instead of second-guessing or buying too many materials, you can save money and ensure the project runs smoothly.

Bespoke designs

Whether it's a residential or commercial property, people love putting a unique stamp on their buildings. Before 3D printing came along, bespoke designs would cost a fortune, as the architect and construction team would have to experiment to ensure safety.

Now, it's possible to conceptualise and test designs using the technology, which means there's more room for creativity.

3D printing in brickmaking

One of the most exciting trends in 3D printing is using the technology to create bricks and streamline the manufacturing process.

As with other construction processes, 3D printing bricks involves layering materials to create a strong brick that boasts thermal properties and durability.

However, many universities and professionals are experimenting with brick 3D printing using other materials, such as plastic (Construction Management).

With these technological advances, exploring other brick construction materials will be possible, resulting in significant cost savings and making building projects more accessible for those on a limited budget.

In terms of construction, 3D printing enables specialists to create digital models, saving resources and time

How does it work?

There are various steps involved in the 3D printing process, and understanding them can help you create bricks that align with building regulations while also saving money. Let's explore the process in more detail.

Choosing materials

Many 3D-printed bricks use a unique concrete mixture, including fibres, cement and sand. Some ingredients promote durability and strength, ensuring the bricks serve their desired purpose.

We can also expect to see more eco-friendly or recycled materials as technology advances.

For example, plastic is known to damage the environment and cause harm to marine life, but turning it into bricks can reduce pollution and promote sustainability.

Modelling

The design and modelling process involves using computer-aided design (CAD) software to create a digital model of the brick shape and consistency.

Doing this enables you to control the size and shape of the brick, tailoring it to your specific design needs. Not only does this facilitate easy customisation, but it also saves money.

Instead of worrying about creating bricks that don't meet the size requirements or aren't consistent with the building's shape, manufacturers can control the process and create unique architectural features.

Printing

Now for the fun part: the printing process. 3D printers can create bricks by depositing materials by each layer. The unique construction process ensures an even distribution of materials for each layer, aligning with the CAD-specified design.

Each layer must undergo curing to ensure it hardens before adding the next layer.

What does the future hold?

As with all new technologies, 3D brick printing does have its challenges, but successfully navigating them ensures it will continue to develop. While universities are undertaking research to assess the durability of these bricks, the initial results look promising.

Manufacturers also need to learn how to implement the technology for large-scale projects, which will require proper utilisation and selection of suitable materials.

However, apart from these minor challenges, the future looks promising. Here's why:

⦿ Flexibility 3D printing allows for more customisation, which means people can specify custom brick shapes for any project. Building exteriors could be as unique as their interiors.

⦿ Efficiency When used correctly, 3D printing can be faster than other manufacturing techniques, which means construction materials might be more accessible.

⦿ Sustainability Perhaps the most prominent future benefit of 3D printing in construction is reducing waste and allowing manufacturers to reuse materials. This will make the industry more sustainable, which is a bonus.

⦿ Cost savings Sourcing superior construction materials can be expensive, but reusing them means the price of bricks could decrease, making them available to more people.

We're here for you

We've seen how 3D printing has benefited numerous industries; now it's construction's turn. When it comes to brick construction, 3D printers will pave the way for a more sustainable future where materials such as plastic can serve a worthy purpose.

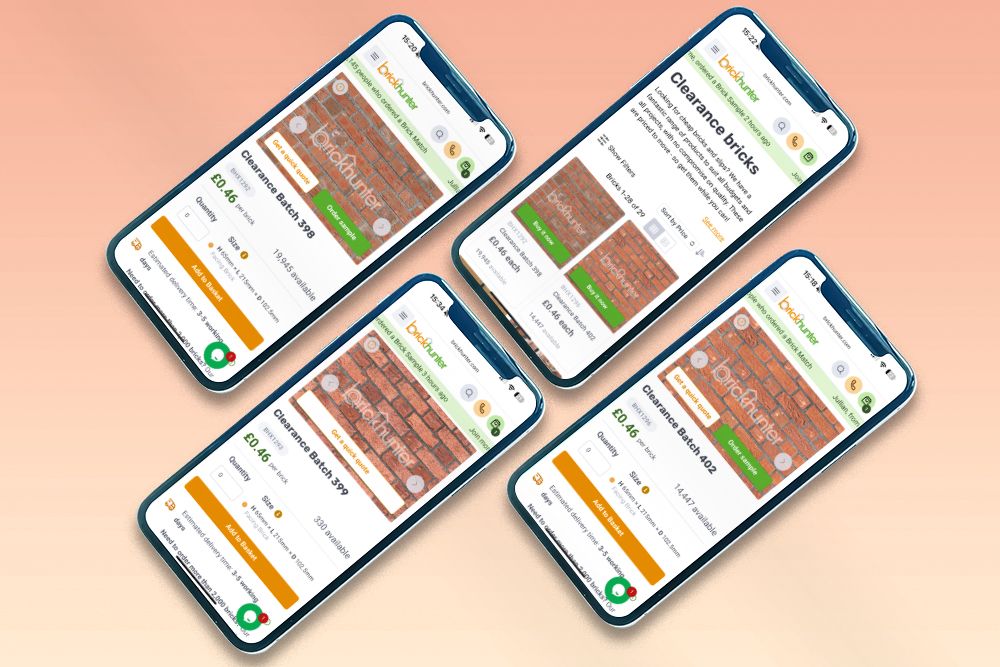

If you're unsure about which bricks to use for your project, our free Brick Selection service could be just what you need; if you want to use bricks that blend seamlessly with the rest of your home, our Brick Matching service could be right up your street; or if you'd prefer to browse bricks for yourself, we have more than 3,600 products to choose from in our Brick Library!

Our expert Brick Advisors are standing by to help you figure out how many bricks you need for your project, then source them and find you the best price - we'll even arrange delivery too!